In this article we will discuss about mushroom cultivation

Mushroom Cultivation

- Mushrooms are the fruiting body of edible fungi, commonly belonging to Basidiomycotina and rarely to Ascomycotina.

- The mushrooms is rich in proteins, fibres, vitamins and minerals.

- In the early years of mushroom culture in the Netherlands, compost was scooped into the mushroom trays and then inoculated with spores. A nine week wait followed, until the mycelium spawned sufficiently, flushing started and the grown mushrooms could be harvested by hand.

- The mushroom cultivation process hasn’t changed that much, but the way the successive steps are performed differ immensely.

- Mushroom cultivation can be divided into five phases: Composting, Spawning, Casing, Pinning and Harvesting

Steps of Mushroom Cultivation

Phase 1: Composting

- The growing cycle of mushroom cultivation starts with compost.

- Compost preparation starts with horse manure, get it from large horse breeding companies.

- Straw, gypsum, chicken manure and water are added to the horse manure.

- Commonly 100 kg of dung is mixed with 33 kg of straw.

- Gypsum is added @ 25 kg/tonne (1,000 kg) dung.

- The straw improves the structure, gypsum ensures the proper acidity and the two manures are the nutrients.

- The compost is produced in tunnels in order to prevent the smell.

- Air purification with ammonia wash prevents gas emissions from manure.

- It is kept at about 50oC for one week.

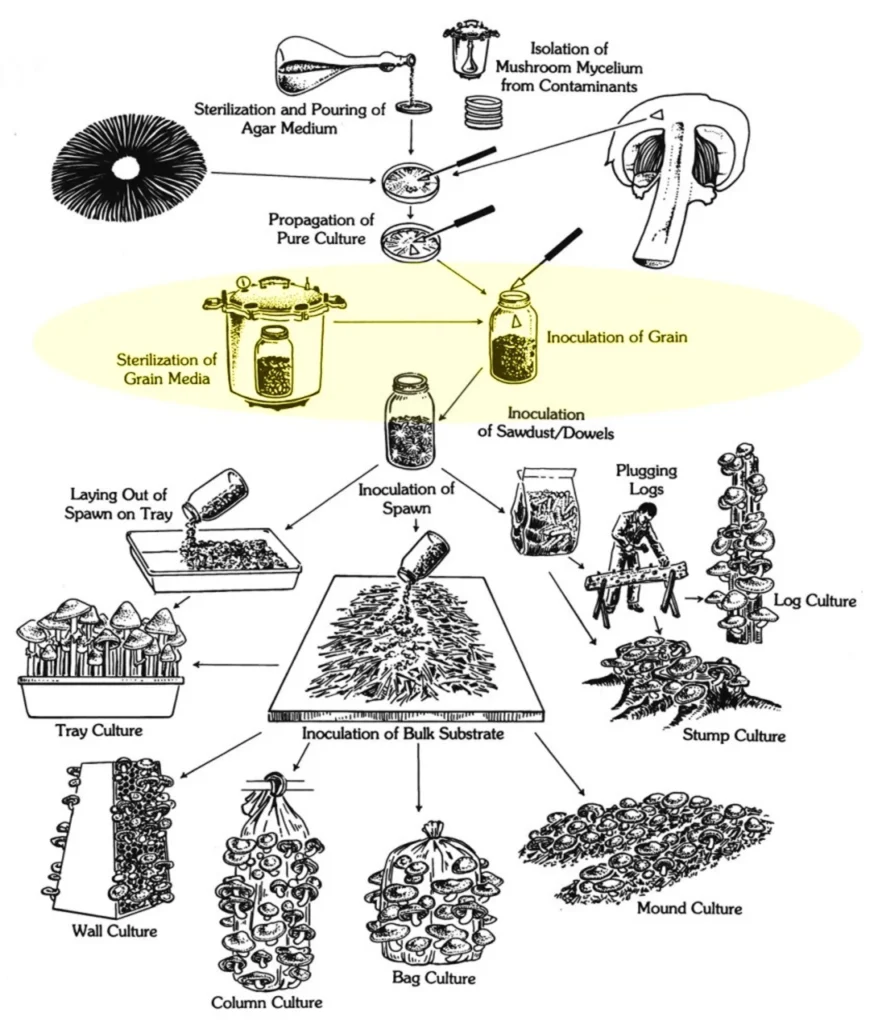

Phase 2: Spawning

- Fresh compost is pasteurized in a tunnel at 57-60°C to kill bacteria.

- The compost is mixed with spawn (mycelium) that produces mushrooms.

- Compost is moved to another tunnel for mycelium to spread.

- Mycelium fully permeates the compost in two weeks, making it ready for growers.

- Spawn production is a sophisticated process managed by dedicated companies:

- Grain is sterilized to prevent infection.

- Spores are inoculated into the grain.

- Grain is incubated for two weeks at 25°C, then transferred to refrigerator at 2°C to harden it.

- The spawn gets a shelf life of 6 months without the mycelium losing its vitality

Phase 3: Casing

- The matured compost is spread onto long stainless steel boxes, the mushroom beds.

- The beds are inside special dark rooms called cells.

- The temperature in the cells is kept warm, at about 23 degrees Celsius.

- A layer of peat casing material is added on top of the compost to keep the compost moist.

- Over a period of six days, 20 to 25 litres of water is sprinkled on each cell because more moisture is needed.

- After this, the fungus has two days to grow through the covering layer of casing soil.

Phase 4: Pinning

- Mushrooms grow naturally in autumn but can be cultivated year-round by simulating autumn conditions.

- Temperature in the cell is gradually lowered from 23°C to 17°C over four days.

- The temperature drop signals the mycelium to start sprouting mushrooms, similar to nature’s process.

- Once mycelium fully grows, it begins forming small buds called pins, which develop into mushrooms.

- Air temperature and humidity affect mushroom growth:

- Low temperature and humidity: More buds, smaller mushrooms.

- High temperature and humidity: Fewer buds, larger mushrooms.

Phase 5: Harvesting

- The temperature is kept steady at 18 degrees Celsius. Mushrooms grow best at this temperature.

- Mushrooms will grow 3 cm (1 inch) in a week, In week 3 the first flush is harvested.

- The selling fresh mushrooms are still harvested by hand.

- Hand-picking ensures mushrooms are removed undamaged.

- On average, a picker can harvest between 18 and 30 kilos of mushrooms an hour

- Nine days after the first flush, the second flush will be harvested.

- The second flush often consists of larger, but fewer mushrooms than the first flush.

Preservation of Mushrooms

- Discolouration, weight, and flavourloss are the main problems of harvesting stage of mushrooms.

- The following methods are used to Preservation of Mushrooms.

- Canning: Mushrooms are washed, blanched in hot water and citric acid (3-5 minutes)

- Drying: Preservation by reducing the moisture Content.

- Freezing: Subjecting to low temperature (-60°C)

- Chemical Preservation : such as SO2, sorbic acid, sodium benzoate, ascorbic acid, acetic acid, citric acid.

- Pickling: with salt, oil, spices and vinegar

- Steeping preservation: With salt solution