News

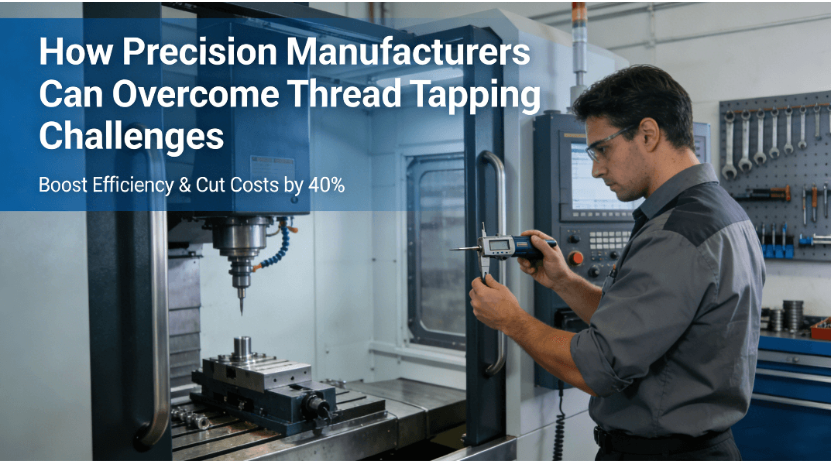

How Precision Manufacturers Can Overcome Thread Tapping Challenges to Boost Efficiency and Cut Costs by 40%

In the precision manufacturing industry, thread tapping is known to be one of the bottlenecks experienced in the production lines. This is because manufacturers are normally associated with problems of premature tap wear, lack of quality threads, and, at times, tap breakages, among others. This is due to the fact that there is no scientific approach to link the type of tap to be used and the material it is dealing with, among others.

This piece offers a comprehensive, data-informed approach to choosing taps, or threads, to help readers form effective approaches to improve consistency, durability, and, most importantly, reduce costs. To better understand how materials, tap geometrics, and tap parameters work in tandem, manufacturers can turn their threading process around by considering the aspects that are explored below.

What Constitutes a Scientific Approach to Thread Tap Selection?

Scientific method of taper selection in taps goes beyond the trial-and-error process because scientific selection optimizes the decision-making process by considering a number of factors such as the material of the workpiece, the type of thread, and the machining conditions.

1. Difference between Scientific & Empirical Methods

Empirical approaches work by relying on past experiences, often in the form of guidelines. Such methods tend not to work in complex situations. In scientific thread tap selection, there is reliance on scientific principles and real-time information, often in relation to matters such as the hardness of the material and geometry of the holes.

2. Key Variables in Systematic Tap Selection

These key variables are raw material type (for instance, aluminum or stainless steel), thread type (blind or through hole), and machining variables such as rigidity and cooling rates. By evaluating all such variables, one can easily eliminate mistakes such as clogging due to chips or tool breakage. Adding databases or software for thread taps also makes this process easier.

3. Implementing Data-Driven Decision Making

To incorporate data-informed decisions, one needs to focus on the historical data of performance, feasibility studies, and predictions. For example, tracking the tap lifecycle and failure rates can assist in improving the criteria of selection. A proactive approach ensures that there is continuous improvement and it is according to quality requirements, such as ISO 9001.

How Does Material Composition Dictate the Optimal Tap Geometry?

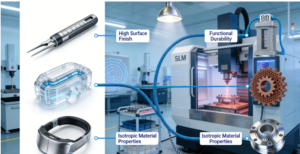

Properties of materials can directly affect tap geometry, since various materials need to be handled in different ways regarding cutting force, heat, and chip removal. This knowledge is critical in determining which type of tap to use in production.

1. Tap Geometry for Different Material Families

For aluminum, being soft and sticky, the best kind of tap for use is the high helix angle spiral flute tap. In the case of hard materials, such as stainless steel, the best type of tap for use is the spiral point tap. Quotations included from reliable sources like the ASM Handbook Volume 01: Properties and Selection: Irons, Steels, and high performance alloys add to the validity of the suggestions.

2. The Role of Helix Angle and Flute Design

The value of the helix angle and the flute type influence the chip management in tapping. A higher value of the helix angle is beneficial for non-ferrous materials, which removes chips from blind holes, whereas a smaller value is better for brittle materials, including cast iron. Because these factors promote chip packing, they directly affect efficiency in the thread tap.

3. Case Examples Based on Material Groups

For instance, in machining the high-temperature alloy, one requires a tap with a coating of TiCN and positive rake angle to resist wear. Again, in machining plastic material, one requires a polish surface tap to prevent material binding to the surface. These scenarios depict how each type of material requires taps with unique geometry to prevent defects.

What Are the Key Parameters for Maximizing Thread Tap Efficiency and Tool Life?

The process parameters of cutting speed, feed rate, and coolant delivery need to be optimized and are critical for obtaining the maximum possible performance of the tap.

- Optimizing Tapping Speed and Feed Rates: Optimizing tap speed and feed rate is essentially optimizing the aggressiveness and accuracy. Higher tap speed means lower cycle time and increased heat generation, whereas unconservative feed can result in poor chip removal. Based on the work material recommendations, improving efficiencies of up to 30% can be achieved without compromising the quality.

- The Impact of Coolant and Lubrication: The type of coolant used and the coolant pressure is an important factor in cooling and chip evacuation. For example, high pressurecooling systems increase the efficiency in deep-hole tapping by reducing friction. The type of coolant used will increase tool life, hence reducing the cost of thread tapping.

- Parameters Monitoring and Adjustment Within Real-Time: By using sensors for torque and vibration monitoring, there is real-time parameter adjustment. This helps to avoid the breakage of taps and helps in maintaining consistency. Its implementation in the form of a scientific approach brings improvement in efficiency and cost-cutting.

How Can Manufacturers Meet Consistent Accuracy in Mass Production of Tapping?

Precision in mass production calls for process control and quality assurance. This is important for achieving consistency, which contributes to meeting industry standards.

1. Implementation of Statistical Process Control (SPC)

SPC methods analyze production data for early signs of deviations. Based on thread depth and diameter, for example, it becomes possible to control the accuracy of thread tapping for large series products. This fits well into the standards mentioned in ISO 9001, which emphasizes process validation.

2. Tool Life Management and Predictive Maintenance

proactive management of tool lives includes replacing the taps based on past data. For instance, the use of torque limits in the change of taps prevents macro-defects in the taps. Such an approach ensures that the taps function effectively in the CNC tapping operations.

3. Quality Assurance through Certification

Companies that comply with certifications such as ISO 9001 and IATF 16949 have developed procedures for the management of the tools. These provide traceability and the assurance that every thread conforms to specifications, which again builds confidence in the accuracy of the thread tapping solutions.

What Framework Enables a True Cost-Effective Thread Tapping Strategy?

Switching the focus from initial tap cost to total cost per hole is essential for achieving long-term savings. The complete framework analyzes all the different cost components comprised of tool procurement, downtime, and scrap.

- Analyzing Total Cost per Hole: Cost-effective thread tapping considers a number of factors, including tool life, machining time, and rejection rates. For example, a premium tap may have a longer life, although more expensive initially, thus it is cheaper overall. A detailed model for thread tapping cost analysis gives justification for such decisions.

- Case Study: Optimization for Cost Reduction: Automotive Parts Case: Optimizing tap selection and parameters reduced the cost by 40% due to reduced tool changes and scrap. This shows that the scientific approach yields tangible benefits. For further insight, read the following about resources on CNC milling services which discuss cost models.

- Cost-benefit analysis in planning: Cost-benefit analysis in production planning ensures that decisions are well-considered. With the help of lifecycle cost calculators, among other tools, options can be reviewed to strategically alter course to cost-effective thread tapping without compromising quality.

How to Evaluate a Supplier’s Capability in Delivering Reliable Thread Machining Solutions?

Supplier selection includes an assessment of technical capabilities, certification, and reputation. A proper evaluation then gives assurance that the partner is well capable of providing good services.

1. Technical Capabilities Assessment and Databases

A reliable supplier should come with comprehensive material databases and case studies. For example, verifying their experience with projects such as engine block threading indicates capability. This checks the box for the criteria in finding a reliable CNC tapping services partner.

2. The Importance of Industry Certifications

AS9100D and other certifications dealing with aerospace signals that the companies manufacturing these parts work to very high standards. Thus, those suppliers have a right to say that they are committed to quality and will be able to make better preparation for such a large volume of CNC tapping services.

3. Rating of Engineering Support and Responsiveness

Strong engineering support teams offer customized solutions and fast response. Assessing their DFM analysis offering and customer reviews provides an idea of reliability and assurances of fit for a precision-driven project.

Conclusion

Thread tap selection is well served by a scientific, systematic approach to overcome efficiency and cost challenges. With data-driven methods, quality consistency is possible along with minimization of waste and enhancement of profitability. Threading, a bottleneck, is transformed into a competitive advantage with this strategy.

FAQs

Q1: What is the first step in selecting the right thread tap?

A: Proper workpiece material and hole specification analysis is the first step. Depending on material hardness and machinability, tap material and geometry are prescribed in order to avoid any chip-packing problem that can easily arise.

Q2: How can I know if a tap will be needed to be replaced prior to producing scrap parts?

A: Look for symptoms, such as increased tapping torque, or deterioration in surface finish. Data-based proactive management in tool life avoids quality issues in mass production.

Q3: What are the main differences between the hand taps and machine taps for the CNC applications?

A: Yes. The tolerances and geometries are tighter to run at high speeds. Using hand taps in the CNC machines results in poor quality and rapid failure.

Q4: What are the benefits offered by the use of spiral-pointed taps over the use of the spiral-fluted ?

A: Spiral point taps remove chips by pushing them through for through holes, while removing chips from blind holes requires pulling them with a spiral fluted tap. This is dependent on the type of hole being drilled to avoid accumulation of chips.

Q5: What is the effect of coating on a tap?

A: Coated materials such as TiN have low friction and long lifetimes. The use of coatings optimized for certain materials leads to improved performance.

Author Bio

The author is a precision manufacturing specialist with LS Manufacturing, a company which assists engineers in overcoming difficult part challenges in sectors such as aviation and autos. ISO 9001 and AS9100D certified, they provide quality services to their clients using their technological expertise. To receive a data-driven thread machining quote and DFM analysis, click here through their online custom CNC milling services

Blog8 months ago

Blog8 months ago[PPT] Human Reproduction Class 12 Notes

- Blog8 months ago

Contribution of Indian Phycologists (4 Famous Algologist)

- Blog8 months ago

PG TRB Botany Study Material PDF Free Download

Blog8 months ago

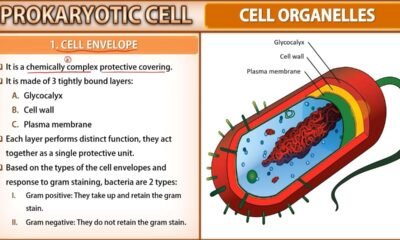

Blog8 months agoCell The Unit of Life Complete Notes | Class 11 & NEET Free Notes

Blog8 months ago

Blog8 months ago[PPT] The living world Class 11 Notes

Blog8 months ago

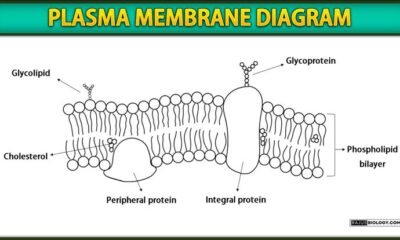

Blog8 months agoPlasma Membrane Structure and Functions | Free Biology Notes

Blog8 months ago

Blog8 months agoJulus General Characteristics | Free Biology Notes

Blog8 months ago

Blog8 months agoClassification of Algae By Fritsch (11 Classes of Algae)