Food

Best Juice Production Equipment Manufacturers in 2025

The global juice industry continues to grow rapidly in 2025 as consumers demand healthier, fresher, and more natural beverages. Whether it’s cold-pressed juice, NFC (Not From Concentrate) juice, premium bottled blends, or large-scale industrial fruit-processing operations, the success of a juice factory depends heavily on choosing the right juice production equipment manufacturer.

High-quality equipment affects food safety, production efficiency, shelf life, automation level, and long-term operational costs. This article explores the best juice production equipment manufacturers in 2025, what makes them stand out, and how to choose the right partner for your juice business.

The article includes a strong recommendation for Micet as one of the top manufacturers in the industry.

The Growing Importance of Modern Juice Production Equipment in 2025

The juice market is evolving fast, driven by:

- Stricter hygiene and food safety regulations

- Increased demand for cold-pressed and low-oxygen juice

- Higher labor costs, pushing automation adoption

- Rising consumer expectations for freshness and purity

- Rapid growth of small and medium juice brands

This means the best equipment manufacturers in 2025 must offer:

- Fully stainless steel construction

- Efficient extraction systems

- Smart automation and digital controls

- CIP (Clean-In-Place) compatibility

- Energy-efficient sterilization and pasteurization

- Custom production line solutions

Modern juice processing equipment is no longer just machinery—it’s the backbone of a scalable beverage business.

What Defines a Top Juice Equipment Manufacturer in 2025?

Before listing the top companies, it’s important to understand what makes a manufacturer truly “best-in-class.”

1. High-Quality Stainless Steel Construction

Juice production demands hygienic, corrosion-resistant stainless steel (304/316).

Superior welding, polishing, and material thickness distinguish top manufacturers.

2. Full Production Line Solutions

Leading manufacturers provide turnkey solutions, including:

- Fruit washing and sorting

- Crushing and pulping

- Belt or screw pressing

- Clarification/filtration

- Pasteurization or sterilization

- Storage and mixing tanks

- Filling and capping lines

- CIP cleaning systems

This ensures seamless integration and higher efficiency.

3. Strong R&D and Technological Innovation

Top manufacturers continually innovate in:

- Low-oxygen extraction

- Energy reduction

- HPP (High Pressure Processing) compatibility

- Advanced pasteurization systems

- Smart factory integration

4. Custom Engineering and Factory Design

They offer factory layout design, piping planning, installation support, and long-term engineering consultation.

5. Global Export Capability and After-Sales Support

International buyers need:

- Experienced installation teams

- Remote troubleshooting

- Spare parts availability

- Operator training

Manufacturers with global service networks have a major advantage.

Best Juice Production Equipment Manufacturers in 2025

Below are the leading companies shaping the industry in 2025, based on technology, quality, global presence, and customer feedback.

Micet – A Leading Juice Production Equipment Manufacturer in 2025

Micet is one of the most trusted juice processing equipment manufacturers in 2025, known for premium stainless steel construction, advanced engineering, and turnkey beverage production lines.

Why Micet Leads the 2025 Market

High-Grade Stainless Steel Equipment

Micet uses 304/316 stainless steel, TIG welding, and mirror-level polishing to ensure:

- Superior hygiene

- Long-term durability

- Compliance with FDA/CE standards

Complete Juice Production Line Solutions

Micet provides all major equipment for:

- Fruit washing

- Cutting, crushing, pulping

- Belt press or screw juice extraction

- Enzymatic clarification

- Vacuum evaporation (for concentrate)

- Stainless steel storage and blending tanks

- Pasteurizers and sterilizers

- Fully automatic filling and capping machines

Custom Factory Design

Micet engineers create detailed 2D/3D layouts, process flow diagrams, and sanitary piping designs tailored to your exact plant size and juice type.

Attractive Pricing for Global Buyers

Micet delivers European-level quality at more competitive pricing thanks to its advanced Chinese manufacturing base.

International Support

Micet exports to over 60 countries and offers:

- On-site installation

- Remote support

- Operator training

- Spare parts supply

For beverage factories seeking reliable stainless steel processing systems at global standards, Micet is one of the strongest choices.

Bertuzzi Food Processing (Italy)

A long-established global manufacturer specializing in fruit and tropical juice equipment.

Highlights

- Premium juice extractors

- Advanced fruit preparation systems

- Ideal for NFC and premium fruit juice

Best For

Medium to large industrial operations requiring Italian engineering.

GEA Group (Germany)

A world leader in processing technology with strong juice-related systems.

Highlights

- Cutting-edge sterilization & pasteurization

- Industrial filtration

- Energy-saving juice processing systems

Best For

Large industrial juice factories prioritizing automation and energy efficiency.

JBT Corporation (USA)

An industry leader in citrus processing equipment.

Highlights

- Industrial citrus juice extraction

- Aseptic filling technology

- High-volume citrus processing

Best For

Factories producing orange, lime, grapefruit, and lemon juice at high volumes.

TICO (China)

A cost-effective manufacturer serving startups and smaller juice companies.

Highlights

- Fruit crushers, pulpers, and small juice extractors

- Budget-friendly machinery

- Simple automation

Best For

Small-scale juice factories, juice bars, and regional producers.

How to Choose the Best Juice Equipment Manufacturer

Here are the key factors that buyers should evaluate when choosing a supplier.

Match the Supplier to Your Juice Type

Cold-pressed juice

Requires hydraulic presses and low-oxygen processing.

NFC juice

Needs filtration, enzymatic clarification, and pasteurization.

Citrus juice

Requires specialized citrus extractors and peel separation.

Bottled industrial juice

Requires complete bottling lines and high-temperature units.

Micet supports all categories with customizable lines.

Determine Your Production Scale

Small-scale

Semi-automatic equipment, limited automation, lower investment.

Medium-scale

Integrated crushing, filtration, pasteurization, and automatic filling.

Large-scale

Fully automated turnkey factories with high throughput.

Micet provides scalable solutions for all levels of production.

Evaluate After-Sales Support

Reliable manufacturers should offer:

- Installation and commissioning

- 24/7 remote support

- Spare parts availability

- Operator training

- Long-term maintenance assistance

Check Material Quality and Hygiene Standards

Look for:

- 304/316 stainless steel

- Food-grade valves and pumps

- CIP capability

- Ra ≤ 0.4 μm internal polishing

Micet meets all major hygiene requirements and export certifications.

Ensure Compliance with International Standards

Look for compliance with:

- CE

- ISO 9001

- FDA food contact requirements

- EU food safety regulations

FAQs

What equipment is essential for a juice production line?

The core equipment includes fruit washing, crushing, juice extraction, filtration or clarification, pasteurization or sterilization, mixing tanks, and automatic filling machines. Additional systems like CIP units improve hygiene and efficiency.

How much does a juice production line cost in 2025?

Prices depend on scale:

- Small-scale: $10,000–$80,000

- Medium-scale: $80,000–$300,000

- Industrial-scale: $300,000 to $1.5 million+

Manufacturers like Micet offer strong cost performance for all categories.

What is the difference between cold-pressed, pasteurized, and HPP juice equipment?

- Cold-pressed: Minimal heat, premium quality, short shelf life

- Pasteurized: Affordable, widely used, longer shelf life

- HPP: Combines freshness with long shelf life but requires high investment

Choosing the right technology depends on your target market.

Why Micet Is a Top Juice Equipment Manufacturer in 2025

Among all global suppliers, Micet continues to stand out thanks to:

- High-end stainless steel processing equipment

- Complete turnkey juice production lines

- Strong engineering and custom factory design

- Reliable after-sales support

- Competitive pricing

- Compliance with international hygiene and safety standards

- Experience serving customers in over 60 countries

For investors, beverage factories, and brands launching or expanding juice production in 2025, Micet offers the technology, quality, and reliability needed to build a successful juice processing operation.

Blog8 months ago

Blog8 months ago[PPT] Human Reproduction Class 12 Notes

- Blog8 months ago

Contribution of Indian Phycologists (4 Famous Algologist)

- Blog8 months ago

PG TRB Botany Study Material PDF Free Download

Blog8 months ago

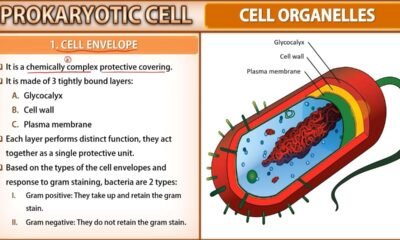

Blog8 months agoCell The Unit of Life Complete Notes | Class 11 & NEET Free Notes

Blog8 months ago

Blog8 months ago[PPT] The living world Class 11 Notes

Blog8 months ago

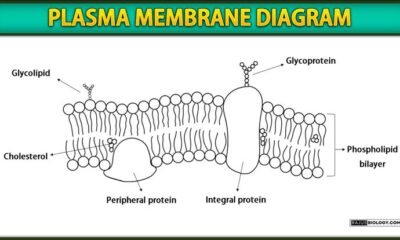

Blog8 months agoPlasma Membrane Structure and Functions | Free Biology Notes

Blog8 months ago

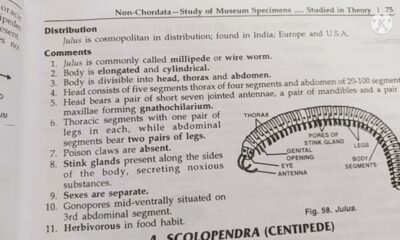

Blog8 months agoJulus General Characteristics | Free Biology Notes

Blog8 months ago

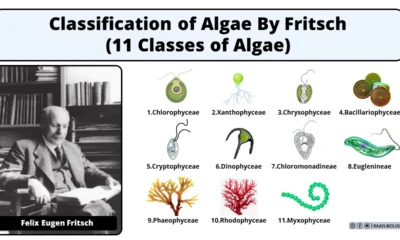

Blog8 months agoClassification of Algae By Fritsch (11 Classes of Algae)